1. Why Lead Time & Warranty Matter So Much for 1–3 Ton Mini Excavators

For importers, dealers, and rental companies, a mini excavator is not just a machine – it’s stock, cashflow, and reputation sitting on a trailer.

Two things decide whether the cooperation with a Chinese supplier feels “easy” or “painful”:

- Lead time: When exactly can the machines be loaded and shipped?

- Warranty: When something fails on a jobsite, how fast can it be solved, and who pays?

If lead time slips, machines miss the season (spring–summer in Europe & North America, construction peaks, government tenders).

If warranty is vague, every breakdown turns into long email chains and lost customers.

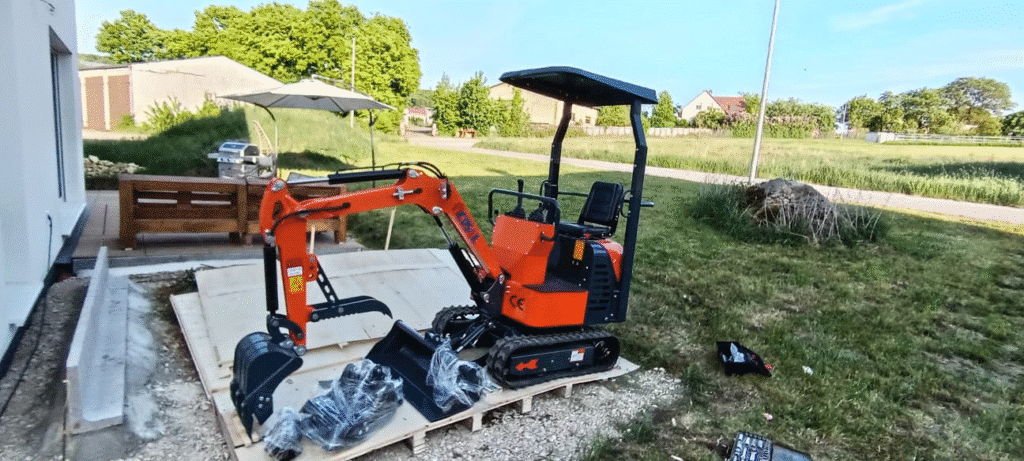

So this article focuses only on lead time and warranty for 1–3 ton Nicosail mini excavators from China – the sweet spot machines for:

- Dealers building their own brand

- Rental companies testing the China-sourced segment

- Small contractors and farmers buying through importers

The goal is simple: make lead time & warranty predictable and transparent, so you can plan stock and protect your margin.

2. Basic Lead Time Concepts When Buying from China

Before talking about Nicosail specifically, it helps to separate a few concepts that often get mixed up:

- Production lead time

Time from deposit / order confirmation to finished machines ready to load at the factory. - Pre-shipment & booking time

Time for:- Final inspection (your own or 3rd party)

- Trucking to port

- Booking vessel space and container loading

- Transit time

Time from Chinese port to your destination port by sea (or rail/land for some Eurasia routes). - Customs & local handling

Time for customs clearance, port handling, and inland trucking to your yard.

In this article, “lead time” mainly talks about production + pre-shipment (factory side). Transit and customs vary too much by route and country to give fixed numbers, but they must be considered in your own planning.

3. Typical Lead Time for 1–3 Ton Nicosail Mini Excavators

Nicosail is not a trading company; it’s a factory with five production lines dedicated mainly to mini excavators and skid loaders. This matters because factories with stable lines usually give more predictable lead times than small workshops that build batch by batch.

3.1 For standard 1–3 ton configurations

For common models (e.g. 1.0T, 1.2T, 1.8T, 2.5T, 3.0T) with standard options and colors that are produced regularly, a realistic production lead time under normal conditions is typically in this range:

- Small trial order (1–3 units):

Around 10–20 days after deposit, if the configuration matches ongoing production. - LCL or small mixed batch (4–10 units):

Roughly 15–25 days. - Full 20’/40’ container mix (10–25 units, 1–3 ton models):

Generally 20–30 days, depending on:- Number of different models

- Custom decals and branding

- Peak or off-peak season

These are realistic planning ranges, not a legal promise. Exact numbers need to be confirmed per order. But for scheduling your sales and marketing, planning with around 3–4 weeks factory lead time for standard 1–3 ton minis is usually safe in normal periods.

3.2 For customized machines or new branding

If you need:

- Custom colors

- Custom stickers / brand name

- Specific engines or hydraulic options

- Special attachments package (thumbs, augers, quick couplers, etc.)

then expect the production lead time to extend by about 7–15 days, mainly because:

- Custom paint and decals need artwork confirmation and sample approval

- Non-standard engines or pumps may need separate purchasing or scheduling

- Extra attachments must be tested for matching and fitment

For new dealers building a private label, the first batch is usually the slowest because all the details are being set for the first time. Once the look and spec are frozen, later batches go much faster and more stable.

4. What Really Affects Your Delivery Time (and How to Control It)

Several practical factors decide whether machines leave on the day you expect or not.

4.1 Seasonality (especially around Chinese New Year)

Around Chinese New Year and sometimes Golden Week, many factories slow down or stop for 2–3 weeks, and ports get congested. If your market’s peak season is spring, it’s wise to:

- Place orders well before the Chinese New Year period

- Confirm lead time in writing in your PI or contract

- Book vessels early, especially for Europe and North America routes

4.2 Order clarity

Unclear specs are a common reason for delays. Lead time only really starts once:

- Model list is confirmed

- Options (cab/canopy, tracks, joystick type, engine choice, extra hydraulic lines) are frozen

- Color and branding artwork are approved

Every time a change is made mid-way (for example, changing engine brand after production starts), it usually pushes the schedule.

4.3 External components supply

Even with in-house welding and assembly, factories still depend on:

- Engines

- Pumps and valves

- Motors and electronic components

A factory with a stable supply chain and stock, like Nicosail, reduces this risk. Nicosail highlights strong supply capability and efficient project planning to keep delivery on schedule. But long-term, it’s still wise for buyers to:

- Share a rough annual forecast

- Place orders in waves, not last-minute

- Stick to a limited number of models and configurations

5. Inside the Nicosail Factory: How Timely Delivery Is Managed

Nicosail positions itself as a China-based mini excavator manufacturer with:

- Five production lines for mini excavators and skid loaders

- Integrated R&D, production, and sales, founded in 2010

- Focus on B2B supply – agents, importers, global distributors with OEM and branding services

This structure matters for you because:

- Capacity is not limited to one workshop or one assembly line

- Machines can be scheduled by model families (1–3 ton lines vs larger models)

- OEM branding fits naturally into their process

Nicosail also emphasizes:

- Quality control and timely delivery as core factory commitments

- Patrol inspection + third-party inspection options for quality assurance before shipment

This combination means a dealer can:

- Fix a lead time target together with the factory

- Use inspection as a “gate” before final payment

- Rely on a structured process rather than improvisation

6. Warranty Basics for 1–3 Ton Chinese Mini Excavators

When evaluating Chinese mini excavators, warranty needs to be looked at in two layers:

- Warranty term itself

- How many years?

- How many operating hours?

- Does it cover major components or just “core parts”?

- Practical after-sales ability

- Can the supplier actually diagnose issues?

- Are spare parts available quickly?

- Is there clear communication and simple procedures?

Many generic mini excavator offers from small factories only provide 1-year warranty on the machine or on “core parts” like engine and pump. That looks good on paper but often lacks detailed terms.

A more serious setup is:

- 2-year / 2000–3000 hours on major systems

- Clear list of covered / excluded items

- Documented claim process and parts support

7. Nicosail Warranty Structure: 3000 Hours / 2 Years Explained

On its mini excavator manufacturer page, Nicosail states a “Long-term warranty – 3000 service hours or 2 years for mini excavators.”

In simple terms, that means:

- Warranty is valid up to 2 years from delivery

- Or up to 3000 operating hours,

- Whichever comes first.

For 1–3 ton mini excavators used in:

- Light construction

- Farm work

- Landscaping

- Rental fleets with moderate utilization

this usually covers at least the first major wear phase of the machine.

7.1 What this tells you as a buyer

- It’s longer than the basic 1-year coverage often found with entry-level suppliers.

- It shows the factory is confident that the structure, hydraulics and key components will survive normal use over that period.

- It allows dealers to offer local customers 1–2 year warranties with some buffer.

Of course, every detailed warranty policy should still be confirmed in writing in the PI or contract for each order, but this 2-year / 3000-hour framework gives a strong reference.

8. What Is Usually Covered – and What Is Not

Exact policy wording may vary by contract and destination market, but for 1–3 ton Nicosail mini excavators, coverage can be understood in typical groups.

8.1 Normally covered (under normal use)

Under a 2-year / 3000-hour framework, dealers can expect coverage for manufacturing defects in major systems such as:

- Main structural components

- Boom, arm, chassis, upper frame, key welds

- Hydraulic system components

- Main pump, control valve, swing motor, travel motors, main cylinders (boom, arm, bucket)

- Power system (depending on engine brand agreement)

- Engine block and key internal components

- Rotating & swing structure

- Swing bearing, swing gear (if failure results from manufacturing defect)

- Major functional components

- Joystick control system, key electronic control modules, travel gearboxes

The idea is: if the machine fails because of a defect in material or assembly, the supplier supports it under warranty.

8.2 Normally not covered (wear, misuse and consumables)

To avoid surprises, it helps to be realistic. No supplier—Chinese or Western—covers everything. The following items are usually excluded or treated as normal wear:

- Wear parts / consumables

- Buckets, bucket teeth, edges

- Tracks (rubber tracks wear depends heavily on use)

- Bushings, pins (after standard wear period)

- Filters, belts, hoses beyond initial failure period

- Fuses, bulbs, standard switch wear

- Damage from misuse or abnormal conditions

- Overloading beyond spec (e.g. lifting heavy rocks with machine too small)

- Serious impact or roll-overs

- Using wrong fuel or lubricants

- Operating in extreme environments without special protection

- Improper maintenance

- Skipped oil changes

- Non-original or low-quality parts causing damage

- Unauthorized modifications (e.g. changing hydraulic settings without guidance)

For dealers and rental companies, the key is to align their customer warranty with the factory warranty, and clearly explain what is considered “normal wear” to end users.

9. How Warranty Support Actually Works for Overseas Buyers

A good warranty is not only about years and hours – it’s about how problems are handled.

For a factory-based supplier like Nicosail, with integrated production and after-sales support, the typical process looks like this:

9.1 Problem reporting

When a failure happens, the local dealer or importer usually provides:

- Machine model and serial number

- Hours on the meter

- Photos and short videos of the fault

- Brief description: working conditions, what happened, error codes if any

The more clear the initial report, the faster the diagnosis.

9.2 Remote diagnosis & solution proposal

Engineering or after-sales teams then:

- Check if the fault is likely manufacturing-related or wear/misuse

- Guide basic checks (pressure tests, voltage checks, visual inspections)

- Decide whether:

- A spare part should be sent

- A local repair with reimbursement is appropriate

- The issue falls under normal wear or misuse

9.3 Parts supply

Because Nicosail is a manufacturer that builds mini excavators in volume, it maintains component supply capability and technical support for its machine range.

For dealers, a practical way is:

- Keep a small local parts stock of common items (seals, cylinders, travel motors, filters, switches)

- Use factory shipments to replenish parts regularly

- For rare or expensive parts, arrange direct shipping from the factory when needed

The combination of factory backup plus local dealer inventory makes warranty handling much smoother.

10. Practical Tips to Protect Your Business on Lead Time & Warranty

Here are concrete actions that serious buyers can take when sourcing 1–3 ton Nicosail mini excavators (or similar machines):

10.1 Lock key points into the PI / contract

Make sure the following are written, not just said:

- Lead time: production days after deposit and final spec confirmation

- Incoterms & port: FOB, CIF, etc. + named port

- Warranty term: clearly write “2 years or 3000 hours,” starting from which point

- Scope of warranty: at least list “main structural components, hydraulic system (pump/valves/motors/cylinders), powertrain, control system”

- Exclusions: wear parts, misuse, improper maintenance

Clarity on paper reduces friction later.

10.2 Build a simple delivery timeline for your sales team

Take a typical case, for example:

- 3 weeks production

- 1 week pre-shipment, inspection & loading

- 4–6 weeks sea transit to Europe or North America

- 1 week customs & inland trucking

From this, your team can see that:

Roughly 9–11 weeks elapse between deposit and machines in the yard, assuming smooth conditions.

If Nicosail confirms 3–4 weeks factory lead time, the rest comes from logistics and customs, which you can manage with your forwarder.

10.3 Plan orders around your peak season

For dealers in Europe and North America:

- For spring–summer demand, container orders are best placed in late autumn to early winter,

avoiding the congestion around Chinese New Year. - For fall utility work, another batch in late spring / early summer often works well.

Because Nicosail is used to working with global distributors and planning project timelines, it’s reasonable to share a rough annual volume plan. This helps the factory line up sub-suppliers and improve on-time performance.

10.4 Align your local warranty policy with Nicosail’s

Typical approach that many dealers use:

- Offer 1-year full machine warranty to end users

- Offer an extra 2nd year warranty on major components (structure, hydraulics, main powertrain)

- Clearly mark what is considered “normal wear” in your own sales agreements

With Nicosail’s 2-year / 3000-hour warranty framework in the background, dealers have space to structure their own terms confidently and still have a cushion from the factory.

10.5 Use third-party inspection when needed

For large orders or first-time cooperation, a third-party inspection can:

- Confirm quantity, configuration, and appearance

- Check key points: serial numbers, options, test operation, welding and painting finishes

- Provide an independent report before final payment

Nicosail itself mentions patrol inspection and third-party inspection as part of its service offering, which makes this step easier to arrange.

11. Quick Summary

For importers, dealers, and rental companies, lead time and warranty are not details – they’re the backbone of a profitable mini excavator line.

For 1–3 ton Nicosail China mini excavators:

- Lead time:

- Standard 1–3 ton models typically need about 2–4 weeks factory production under normal conditions, plus extra days for inspection, loading, and sea transit.

- Custom branding and special specs can add roughly 1–2 weeks.

- Factory capability:

- Nicosail runs five production lines dedicated to mini excavators and skid loaders, with R&D, production, and sales integrated under one roof, aimed at global B2B clients.

- Warranty:

- Mini excavators come with a long-term warranty of 3000 service hours or 2 years, giving dealers a solid base to build their own local warranties.

- Support:

- The brand emphasizes quality control, timely delivery, and technical support for distributors and importers, backed by patrol and third-party inspection options.

Handled properly, these machines can be a reliable and profitable product line, especially for buyers who value factory-level cooperation instead of pure trading.

12. FAQ – Lead Time & Warranty for 1–3 Ton Nicosail Mini Excavators

Q1. What is the standard warranty for Nicosail 1–3 ton mini excavators?

Nicosail states a long-term warranty of 3000 service hours or 2 years for mini excavators. This usually covers core systems such as the structure, hydraulics, and main components against manufacturing defects. Exact written terms should be confirmed in your PI or purchase contract.

Q2. When does the 2-year / 3000-hour warranty start?

In most international machinery deals, warranty starts from the date of shipment or the date of arrival (depending on agreement). To avoid confusion, the start date should be clearly specified in the PI/contract. This allows you to know exactly when coverage begins for each batch.

Q3. How long does it typically take to receive a 1–3 ton Nicosail mini excavator order?

For standard configurations:

- Around 2–4 weeks production lead time from deposit and final spec confirmation

- Plus about 1 week for inspection, trucking, and loading

- Plus sea transit time (often 4–6 weeks to Europe or North America, depending on route)

In total, a realistic planning window from deposit to arrival in your yard is often around 9–11 weeks, assuming smooth logistics.

Q4. How does customization affect lead time?

Customization (special colors, private logos, non-standard engines, special attachments packages) can add about 7–15 days to production lead time. The first customized batch is usually slower because artwork and specifications must be confirmed. After that, repeat orders with the same spec are faster and more predictable.

Q5. What parts are usually not covered by warranty?

Commonly excluded items include:

- Wear parts: bucket teeth, cutting edges, rubber tracks, pins and bushings after normal wear

- Consumables: filters, belts, oils, standard hoses after initial issue period

- Damage from misuse: overloading, accidents, improper operation

- Damage from lack of maintenance: skipped oil changes, wrong lubricants, unauthorized modifications

These points should be aligned with your local warranty terms to avoid disputes with your end customers.

Q6. How are warranty claims handled if the machine is overseas?

The usual procedure is:

- You report the issue with serial number, hours, photos, and videos.

- The factory’s after-sales/engineering team checks the information and may ask for additional tests.

- If considered a warranty case, the factory arranges spare parts shipment or compensates local repair according to the agreed policy.

- For non-warranty or wear-related issues, the factory can still support by offering parts at dealer pricing and technical guidance.

Working with a factory-focused brand like Nicosail, which emphasizes technical support and stable supply, helps keep this process smoother.

Q7. How can a dealer reduce the risk of late deliveries?

Practical steps include:

- Ordering before peak seasons and before Chinese New Year

- Freezing specifications early and avoiding mid-order changes

- Putting lead time and delivery terms in writing in the PI/contract

- Sharing rough forecasts so the factory can plan materials and production

- Using third-party inspection to avoid last-minute surprises

With clear communication and realistic planning, 1–3 ton Nicosail mini excavators can be delivered on a consistent, predictable schedule that supports a profitable dealership or rental business.