Choosing between a 0.8 ton and 1 ton China mini excavator looks like a small decision on paper – just 200 kg difference, right?

In real jobs, that “little” difference often decides:

- Can the machine work safely on a slope?

- Can it lift that concrete slab or pallet?

- Can it get through a garden gate or doorway?

- Will it pass local inspection and keep customers happy?

This guide breaks it down in simple, practical language, from a factory and jobsite point of view – so buyers, dealers, and small contractors can choose with confidence.

1. What “0.8 Ton” and “1 Ton” Really Mean

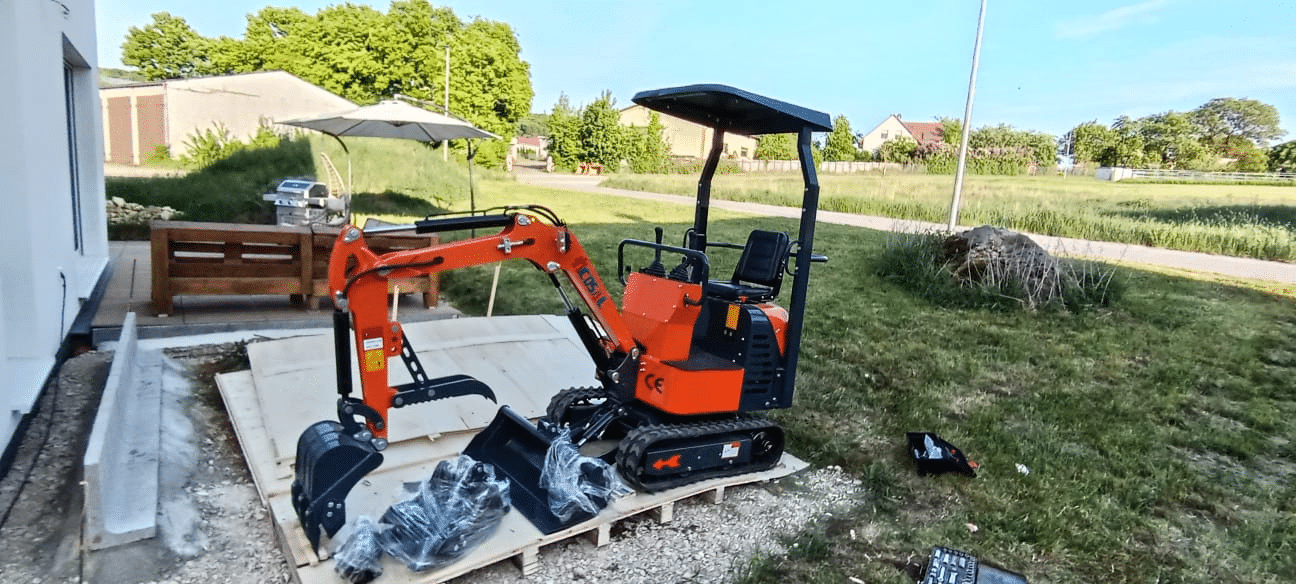

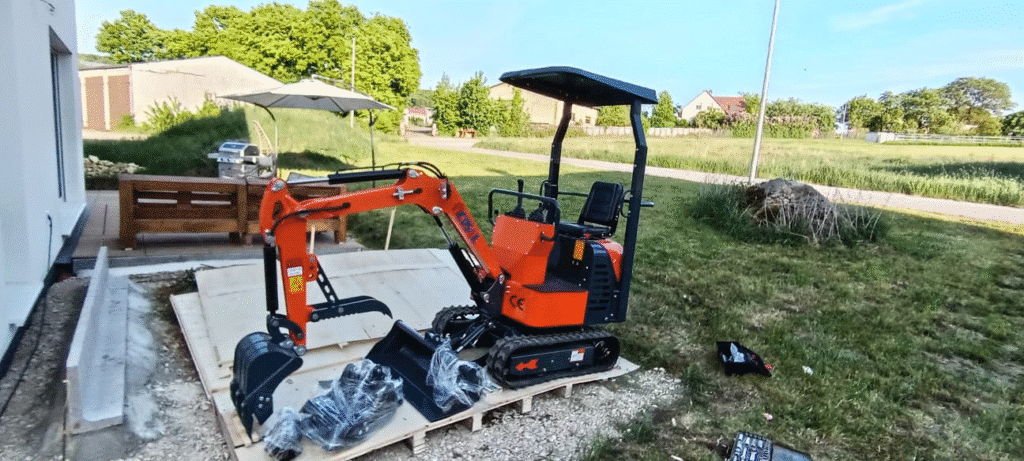

In mini excavator language, “0.8 ton” and “1 ton” usually refer to the operating weight of the machine—roughly how heavy it is with standard equipment, fuel, and operator.

Typical China mini excavators in these ranges:

- 0.8 ton mini excavator

- Operating weight: ~780–880 kg

- Bucket capacity: ~0.02–0.03 m³

- Digging depth: ~1.4–1.7 m

- Width: ~700–900 mm

- 1 ton mini excavator

- Operating weight: ~950–1100 kg

- Bucket capacity: ~0.025–0.04 m³

- Digging depth: ~1.7–2.0 m

- Width: ~900–1000 mm (often with retractable undercarriage)

Numbers vary by manufacturer, but the pattern is similar:

1 ton machines are a bit bigger, stronger, and more stable, but also heavier and slightly bulkier.

2. Key Differences at a Glance

2.1 Size and Transport

0.8 Ton:

- Easier to move on small trailers, light trucks, or even inside vans (depending on local laws and ramps).

- Narrower overall width – better for tight gardens, narrow gates, doorways, and greenhouses.

- Lighter weight reduces stress on floors, pavements, and lawns.

1 Ton:

- Still very compact, but usually 10–20 cm wider and a bit longer.

- Needs a slightly stronger trailer and towing vehicle (more legal margin on total weight).

- Better road stability and less bouncing when being hauled.

For buyers who must pass through sub-800 mm gates regularly, 0.8 ton can be a lifesaver. If the gate is 900–1000 mm, a 1 ton with a retractable undercarriage often works fine.

2.2 Engine and Hydraulics

0.8 Ton Typical Setup:

- Engine power: ~8–10 kW (about 10–13 hp)

- Usually small single- or twin-cylinder diesel or petrol engines.

- Main pump flow: sufficient for basic digging and dozing, but limited for heavy or multiple attachments.

1 Ton Typical Setup:

- Engine power: ~10–14 kW (about 13–19 hp)

- Often uses more recognized engine brands (Kubota, Yanmar, Koop, Changchai etc., depending on the model and emissions requirements).

- Higher hydraulic flow and pressure, so movements are stronger and usually smoother.

What this means on the job:

- 1 ton machine handles harder soil, heavier buckets, and more frequent use of hammer/auger without feeling underpowered.

- 0.8 ton is fine for light digging, trenching in soft soil, and occasional attachments but can feel slow under heavy loads.

2.3 Digging Force and Depth

Rough typical values (these are ranges, not exact numbers):

- 0.8 ton mini excavator

- Max digging depth: ~1.4–1.7 m

- Bucket digging force: lower (soft landscaping and light trenching)

- 1 ton mini excavator

- Max digging depth: ~1.7–2.0 m

- Noticeably higher bucket and arm digging force

On site, this translates to:

- A 1 ton machine can break compacted soil, gravel, and small roots more reliably.

- A 0.8 ton machine may need more passes and might struggle in very hard ground unless the operator is patient.

2.4 Stability and Safety

Stability depends on:

- Machine weight

- Undercarriage width

- Track length on the ground

- Counterweight design

- Boom and arm geometry

General pattern:

- 1 ton machines are more stable with a full bucket, longer reach, or when lifting (like lifting stones, small pallets, or heavy logs).

- 0.8 ton machines can feel a bit “nervous” at full reach with a heavy load, especially on slopes or soft ground.

For rental or for less experienced operators, the extra stability of a 1 ton model often means fewer near-accidents and less stress.

3. 0.8 Ton Mini Excavator: Pros, Cons & Best Use Cases

Pros of 0.8 Ton China Mini Excavator

- Ultra-compact size

- Perfect for backyards, urban gardens, small basements, and indoor work (with proper ventilation).

- Easier to squeeze between trees, fences, walls, and narrow passages.

- Light weight

- Less damage to lawns, paving stones, and delicate surfaces.

- Easier loading and unloading; lighter trailers can be used in many countries.

- Lower purchase price

- Generally cheaper than 1 ton, allowing tighter budgets or more units for the same investment.

- Attractive as an entry-level machine for small contractors and homeowners.

- Lower fuel consumption

- Smaller engine, lower operating cost per hour for light work.

- Friendly for first-time users

- Less intimidating for homeowners and small farm owners.

Cons of 0.8 Ton China Mini Excavator

- Limited digging power

- Struggles with very compact or rocky soil.

- Not ideal for daily heavy-duty use or hammer work.

- Less stability with loads

- Easier to feel “tippy” when lifting or digging at full reach.

- Requires careful operator training and good ballast design.

- Shorter reach and depth

- More repositioning needed to dig longer trenches or deeper holes.

- Attachment limitations

- Hydraulic flow and pressure may not support larger hammers, big augers, or heavy tilt buckets.

- Lower resale in some markets

- In certain regions, 1 ton machines are more popular and easier to resell quickly.

Best Use Cases for 0.8 Ton

- Garden and backyard projects

- Small irrigation channels and shallow trenching

- Greenhouse work and narrow livestock barns

- Small residential demolition (light internal work)

- Compact urban jobs where space is extremely limited

- Occasional use on farms or homesteads

For many private owners and very small contractors, a well-built 0.8 ton machine can cover 80% of typical light jobs at a lower cost.

4. 1 Ton Mini Excavator: Pros, Cons & Best Use Cases

Pros of 1 Ton China Mini Excavator

- Stronger digging force and better reach

- Handles tougher ground and deeper trenches.

- Less repositioning, higher productivity per hour.

- Better stability

- Heavier weight and often wider undercarriage.

- Safer when handling rocks, concrete, or logs.

- More forgiving to new operators.

- More capable with attachments

- Can drive larger augers, hydraulic hammers, rakes, thumbs.

- Better hydraulic performance for continuous attachment work.

- More suitable for professional use

- Fits rental fleets, contractors, small builders, and landscapers.

- Often easier to rent out at a higher daily rate.

- Stronger resale market

- 1 ton mini excavator is a “sweet spot” size in many countries.

- Easier to sell second-hand if the machine is from a reliable factory.

Cons of 1 Ton China Mini Excavator

- Higher purchase price

- Typically several hundred to a couple thousand dollars more than similar 0.8 ton machines.

- Slightly larger and heavier

- May not fit very tight passages under 800–850 mm.

- Requires a stronger trailer and tow vehicle in some markets.

- More ground pressure

- Slightly more marking on soft lawns or delicate surfaces (though still much lighter than 1.5–2 ton machines).

- Higher fuel use

- Still economical, but more fuel than a 0.8 ton for very light tasks.

Best Use Cases for 1 Ton

- Contractors doing daily light-to-medium excavation

- Rental companies targeting homeowners + pros

- Farmers needing regular trenching, drainage, foundations, and small construction

- Small construction sites with typical access (gates ~900 mm or more)

- Any buyer who wants one machine to cover as many jobs as possible

In many markets, if owners can only buy one China mini excavator, they choose 1 ton because it balances price, power, and flexibility very well.

5. How the Difference Shows Up on Real Jobs

5.1 For Homeowners & Garden Work

- 0.8 ton is great for planting trees, small ponds, and utility trenches in gardens with tight access.

- If the yard is small, with very narrow gates, or if the owner is worried about lawn damage, a 0.8 ton machine feels “just right”.

- 1 ton is better if the property has:

- Heavy soil

- Many stump and root removals

- Deep trenching for drainage or foundations

Homeowners often think “smaller is always safer,” but in reality, a slightly heavier and more stable 1 ton machine can be easier and safer to use once it fits on site.

5.2 For Farmers & Small Holdings

On farms, machines work harder and more often:

- Digging water lines and drainage

- Cleaning ditches

- Light demolition of old animal shelters

- Handling logs and rocks with a thumb or grab

Here the 1 ton mini excavator tends to pay back faster because:

- It handles heavier loads and harder soil.

- It works with more attachments (auger, hammer, rake, grab).

- It can run longer hours without feeling “overworked”.

A 0.8 ton machine can still make sense for small farms focusing mostly on light trenching and small landscaping.

5.3 For Rental Fleets & Dealers

Rental demands:

- Easy to transport

- Simple for beginners to operate

- Strong enough that customers feel “it really works”

- Low breakdown rate

Most rental fleets prefer 1 ton for a few reasons:

- Customers often compare it to “brand-name” 1–1.2 ton machines.

- It feels more powerful and more stable, which means higher satisfaction.

- Daily rental rate is better, so the payback period is shorter.

0.8 ton machines can still be useful in a fleet as special narrow-access units that can be marketed for “ultra tight spaces”.

5.4 For Contractors & Builders

Builders and contractors care about:

- Productivity (how many meters of trench per day)

- Safety and risk of tipping

- Ability to handle unpredictable soil and small lifting jobs

In this group, 1 ton is usually the minimum recommended size for a main “everyday” mini excavator:

- Enough power for typical foundations, drainage, and utility work.

- Acceptable performance with small breakers and augers.

- Can be used as a “helper machine” even when larger excavators are on site.

A 0.8 ton model often becomes a special tool for tight indoor or backyard jobs, not the main workhorse.

6. Price, Profit and Total Cost of Ownership

When comparing 0.8 ton vs 1 ton from China, most buyers look only at FOB/EXW price. That is only half the story.

Things to consider:

- Purchase Price

- 0.8 ton: lower initial cost.

- 1 ton: typically 5–20% more, depending on engine brand, options, and factory.

- Productivity

- 1 ton may dig 20–40% faster due to higher force, better reach, and less repositioning.

- If machines are rented out or working daily, that speed quickly pays back the extra cost.

- Fuel and Operating Cost

- 0.8 ton: lower fuel consumption per hour.

- 1 ton: slightly higher fuel, but more work gets done per hour, so fuel per cubic meter of soil moved can actually be similar or better.

- Maintenance and Spare Parts

This depends heavily on the manufacturer:

- Cheap components and poor welding → more downtime, higher repair cost.

- Better materials, hoses, seals, and paint → longer life, higher resale value.

- Resale Value

- 1 ton mini excavator with a clean service history and recognizable engine brand often brings better resale money than a smaller and less known 0.8 ton unit.

For serious users or dealers, 1 ton often gives a better lifetime profit, while 0.8 ton wins mainly on initial price and extreme compactness.

7. Quality Differences Between China Mini Excavator Brands

Not all China mini excavators are built the same, even if they look similar in photos.

Key things that separate a serious factory (like Nicosail) from “garage” producers:

7.1 Steel Structure and Welding

- Proper thickness of boom, arm, and chassis plates.

- Reinforcement at high-stress areas (boom foot, arm base, bucket linkage).

- Welding procedures (WPS), skilled welders, and ultrasonic crack checks.

Weak points show up after hundreds of hours, not in the first few days. Cracks, broken bushings, and twisted booms are often signs of poor design or thin materials.

7.2 Hydraulic System

- Quality of main valve, gear or piston pump, and travel motors.

- Proper matching between pump flow, cylinder size, and engine power.

- Layout and securing of hoses to avoid rubbing, kinking, and leaks.

A well-matched system feels:

- Smooth on joystick

- Strong without stalling

- Stable when slewing and driving

Nicosail and other serious manufacturers put real effort into hydraulic matching and leak control, because that’s where many cheap machines fail.

7.3 Engine and Emissions Compliance

For Europe, North America and Australia, buyers must look at:

- EU Stage V / EPA Tier 4 emission compliance

- Noise and safety requirements

- CE and other certificates

Professional factories cooperate with recognized engine brands and can provide:

- Engine certificates

- Emission documents

- Correct labels and manuals in English

This helps avoid customs problems and issues with local authorities.

7.4 Paint, Hoses, Cylinders and Small Details

Long-term reliability also depends on:

- Surface treatment before painting (sandblasting, phosphating, etc.)

- Quality of paint (resistance to UV and chemicals)

- Hose brands, sealing rings, cylinder rod hardness

- Routing of cables, connectors, and quick couplers

Customers usually cannot see these things from catalog photos, but they feel them after 1–2 years of use.

Well-built units may cost a bit more than the cheapest offers, but they save money on:

- Repairs

- Downtime

- Lost rental days

- Lost reputation with end users

Nicosail positions itself in this more reliable segment, offering factory-level quality and customization rather than just “cheapest price”.

8. How to Choose: 0.8 Ton vs 1 Ton Checklist

Here is a practical checklist to guide the decision.

8.1 Site Access

- Gate width < 800 mm → lean toward 0.8 ton.

- Gate width 800–1000 mm → either, but check exact machine width (consider retractable undercarriage).

- Plenty of access → 1 ton makes more sense in most cases.

8.2 Type of Work

- Mostly soft soil, garden, and light trenching → 0.8 or 1 ton both fine.

- Hard, compact soil, small demolition, root removal → 1 ton.

- Regular hammer or auger use → 1 ton strongly recommended.

8.3 Frequency of Use

- Occasional weekend or seasonal use → 0.8 ton can be enough and easier on budget.

- Daily or weekly professional use → 1 ton is safer and more productive.

8.4 Transport Conditions

- Very limited towing capacity or small trailer → 0.8 ton might be better.

- Pickup or bigger trailer available → 1 ton is no problem and brings more performance.

8.5 Budget and Payback

Ask two questions:

- How many hours per year will the excavator work?

- Is the extra price of a 1 ton machine recovered quickly through faster work and higher rental rates?

If the answer is “yes, it pays back in 1–2 years”, then 1 ton is the smart choice.

8.6 Local Market and Resale

- If local customers know and trust 1 ton machines more than 0.8 ton, resale will be easier and quicker.

- Dealers and importers often start with 1 ton models and then add 0.8 ton for special niches.

9. What to Confirm Before Ordering From China

Whether choosing 0.8 ton or 1 ton, it’s important to check a few key points with the supplier.

9.1 Certificates and Compliance

- CE certificate (for EU)

- Emissions compliance (Stage V, EPA Tier 4, etc., if needed)

- Operation manuals and safety labels in the right language

Serious factories will share sample documents and explain clearly what is genuine and what is not.

9.2 Technical Specs in Writing

Request a spec sheet including:

- Operating weight

- Width, height, and length

- Engine model and power

- Pump flow and system pressure

- Max digging depth and reach

- Standard attachments (bucket size, dozer blade, canopy, etc.)

Then compare 0.8 ton vs 1 ton models side by side.

9.3 Warranty and Spare Parts Support

- Standard warranty period (commonly 1 year, sometimes 2 on major components).

- List of fast-wearing parts and recommended stock for the first year.

- Lead time for critical components if something fails.

Well-organized manufacturers like Nicosail can provide spare parts lists, exploded diagrams, and online support to help dealers and end users.

9.4 Production and Delivery Time

- Confirm realistic lead times, especially before peak seasons (spring for construction and farming in many regions).

- Ask how the factory handles delays and how they communicate during production.

Delays can cost dealers a whole season of sales or rentals, so this point is crucial.

9.5 Customization and Branding

For importers and dealers:

- Ask about color customization, logo placement, and model labels.

- Check if the manufacturer can print local language warnings and manuals.

Nicosail, for example, offers OEM branding and customized paint schemes, which helps dealers build their own brand identity in local markets.

10. Where Nicosail Fits Into the Picture

Nicosail is a China-based factory brand focusing on mini excavators, compact tracked loaders, and skid steer loaders, with multiple production lines and export experience to Europe, North America, and Australia.

For the 0.8 ton vs 1 ton decision, Nicosail:

- Offers both 0.8 ton and 1 ton mini excavators with optimized chassis and hydraulic matching.

- Uses branded engines and carefully selected hydraulic components, aimed at reducing leakage and breakdowns.

- Provides OEM customization (colors, logos, attachments) so dealers can market machines under their own brand.

- Focuses on structural strength and weld quality to avoid early cracks and failures.

The goal is not just to sell a cheap machine, but to help buyers:

- Choose the right size (0.8 or 1 ton)

- Avoid hidden quality issues

- Build a stable, long-term business with repeat customers

Buyers who value reliability and after-sales support often find this more important than saving a few dollars on the initial order.

11. FAQ: 0.8 vs 1 Ton China Mini Excavator

Q1. Is a 1 ton mini excavator much bigger than a 0.8 ton?

Not dramatically, but enough to matter.

A 1 ton is usually 10–20 cm wider and slightly longer. In most gardens and small sites, it still fits easily. The main difference is how it feels on the job: more stable, stronger, and more capable with attachments.

Q2. Can a 0.8 ton excavator run a hydraulic hammer?

For light, occasional hammer work on softer materials, yes.

But for regular breaker use or hard concrete/rock, a 1 ton model is strongly recommended due to better hydraulic flow, cooling, and structural strength.

Q3. Which size is better for a first-time private owner?

If the property has very narrow access and light work: 0.8 ton can be perfect.

If access is normal and there are multiple jobs (trenching, landscaping, small foundations, tree removal): 1 ton often gives more value and flexibility.

Q4. Is the fuel consumption of a 1 ton excavator much higher?

Fuel consumption per hour is higher, but the 1 ton machine also does more work per hour.

In many cases, fuel per cubic meter of soil moved is similar or even better for 1 ton. For occasional hobby use, the difference is not a big issue.

Q5. Are 0.8 ton machines less durable than 1 ton?

Durability depends more on the factory, design, and components than the size itself.

However, many low-cost 0.8 ton machines on the market are built with minimal materials, so choosing a reliable manufacturer like Nicosail makes a big difference.

Q6. What size should a dealer start with when importing from China?

Many dealers and rental companies start with 1 ton models because:

- They are easier to market

- They suit both homeowners and professionals

- They offer good rental rates and resale value

Once that line is established, adding a 0.8 ton range for narrow-access or budget customers works very well.

Q7. Can both 0.8 ton and 1 ton excavators be customized with my own brand?

Yes, serious factories can customize:

- Paint colors

- Logos and model names

- Decals and labeling

- Sometimes even control layout and options

Nicosail supports this kind of customization for distributors and dealers, which helps build local brands.

12. Final Summary

The choice between a 0.8 ton and 1 ton China mini excavator is more than just a 200 kg difference on a spec sheet.

In simple terms:

- Choose 0.8 ton if:

- Access is extremely tight (gates under ~800 mm).

- Work is mostly light garden, landscaping, and small trenches.

- Budget is tight and usage hours are low to moderate.

- Choose 1 ton if:

- The machine will work regularly on farms, construction, or rental fleets.

- Soil can be hard, and attachments like hammers or augers are needed.

- Stability, digging power, and resale value are important.

Above all, the quality of the manufacturer matters as much as the size. A well-engineered 0.8 ton or 1 ton machine from a factory like Nicosail, with good hydraulics, strong structure, and proper after-sales support, will always beat a “no-name” machine that only looks good in pictures.

With a clear view of access, job types, and payback, buyers can decide confidently:

- 0.8 ton: the compact specialist for tight spaces and light work.

- 1 ton: the all-round workhorse for serious jobs and long-term profit.

Both sizes have their place. The key is matching the machine to the real work it will do – and choosing a supplier that stands behind every excavator that leaves the factory.