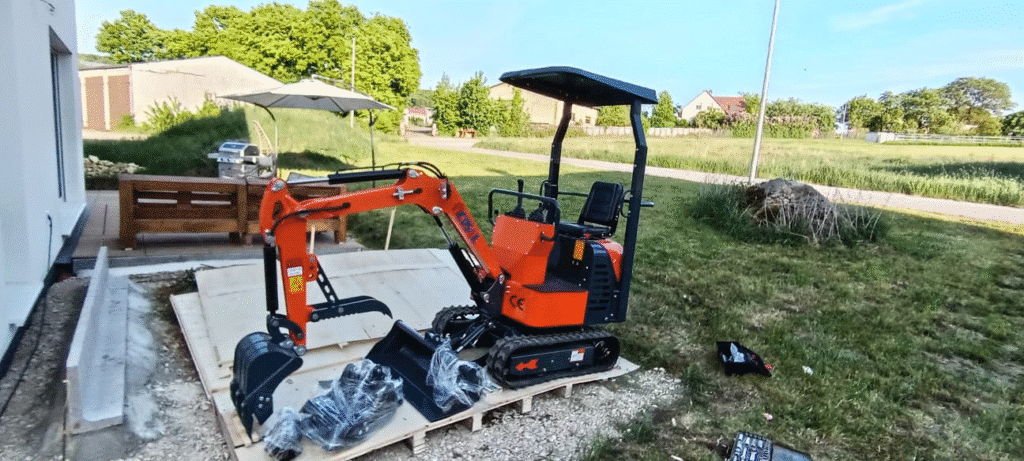

If someone is thinking about buying a 1–3 ton China mini excavator, the real question is not “How much does the machine cost?”

The real question is:

How many hours per year does this mini excavator need to work before it actually makes money?

This question comes up again and again from:

- B2B buyers (dealers, rental companies, importers)

- Small contractors

- Farm and land owners

- People buying their first excavator

The answer is not one single number. It depends on how the machine is used, who is using it, and what kind of work it’s doing.

This article breaks it down in plain English, using real factory-side experience and real buyer cases — no sales talk, no fake online numbers.

1. Why “Working Hours” Matter More Than Machine Price

Many buyers focus only on purchase price.

But two machines with the same price can have very different profitability, depending on:

- How many hours they work per year

- How much downtime they have

- How expensive repairs become after 2–3 years

In simple terms:

- A cheap machine that works 300 hours/year = slow payback

- A solid machine that works 1,000+ hours/year = fast return

That’s why experienced buyers always ask:

“How many hours can this machine work every year without trouble?”

2. Typical Annual Working Hours for 1–3 Ton Mini Excavators

Based on real usage data from Europe, North America, and Australia, here is a very realistic range:

| User Type | Annual Working Hours |

|---|---|

| Private land owner | 200–400 hours |

| Small contractor | 600–1,200 hours |

| Rental machine | 800–1,600 hours |

| Municipal / utility | 1,200–2,000 hours |

For 1–3 ton mini excavators, most profitable users sit between:

600 to 1,500 hours per year

That range is the key for ROI.

3. Profit Model #1: Owner-Operator (Farmers & Small Contractors)

This is the most common buyer type.

Typical situation:

- Owns one mini excavator

- Uses it for fencing, trenching, drainage, landscaping

- Sometimes works for neighbors or small jobs

Annual hours:

- 500–1,000 hours

Profit logic (simple):

- Machine cost spread over 3–5 years

- Fuel and maintenance are manageable

- No rental pressure or rush

💡 Break-even point:

Usually around 700–900 hours total, not per year.

That means:

- If the machine works 700 hours per year, it can pay itself off in 12–18 months

4. Profit Model #2: Rental Business

Rental buyers look at hours very differently.

Typical rental usage:

- Short jobs

- Many operators

- Less care, more wear

Annual hours:

- 800–1,600 hours

Rental companies usually calculate:

- Hourly rental rate × expected yearly hours

- Minus downtime and repairs

💡 Key rule in rental:

If a mini excavator cannot reliably work 1,200+ hours/year, it is not a good rental machine.

That’s why rental buyers focus heavily on:

- Engine brand

- Hydraulic hose quality

- Electrical system reliability

5. Profit Model #3: Dealer / Importer / Rebranding Business

This group thinks differently.

They care about:

- Total lifetime hours

- Appearance after 1–2 years

- Warranty claim rate

Typical machine lifecycle:

- Sold new

- Works 1,000–1,500 hours/year

- Resold or replaced after 3–5 years

💡 Dealers prefer machines that can reach:

6,000–8,000 total hours without major overhaul

That’s where factory quality control becomes invisible but critical.

6. The Sweet Spot: Minimum vs Ideal Working Hours

Let’s make this very clear.

Minimum hours to be “worth buying”:

- 300–400 hours/year

Below this, renting may be cheaper.

Ideal profit zone:

- 700–1,200 hours/year

Heavy use (acceptable if machine is well-built):

- 1,500–2,000 hours/year

Anything above that requires:

- Strong hydraulics

- Good cooling system

- Reliable engine sourcing

7. What Happens If the Machine Works Too Little?

This sounds strange, but it happens.

Problems with low usage:

- Seals dry out

- Battery failure

- Rust in hydraulic components

- Fuel system issues

Machines working under 200 hours/year often age worse than machines working regularly.

8. What Happens If the Machine Works Too Much?

Overworking is also risky.

Common issues after 1,800+ hours/year:

- Hydraulic pump fatigue

- Pin and bushing wear

- Electrical connector failures

This is where cheap machines fail first.

Better-built China mini excavators use:

- Thicker steel in boom and arm

- Better hose routing

- More stable hydraulic valves

9. Maintenance Costs by Working Hours (Simple Breakdown)

Very rough but realistic:

| Hours / Year | Maintenance Cost |

|---|---|

| 300–500 | Low |

| 600–1,000 | Normal |

| 1,200–1,600 | Medium |

| 1,800+ | High |

Most owners feel comfortable around 800–1,200 hours/year.

10. How Chinese Mini Excavators Compare on Hour-Based ROI

China mini excavators have changed a lot in the last 10 years.

Today:

- Engines are more standardized

- Hydraulics are more consistent

- Welding and machining are more controlled

The biggest difference between factories is not the design —

it’s how strictly parts selection and testing are done.

That’s why some machines stop at 3,000 hours, while others run past 8,000 hours.

11. Real Factory Insight: Why Some Machines Reach 8,000+ Hours

From factory-side observation, long-life machines usually have:

- Proper hose length (not stretched)

- Clean hydraulic oil from day one

- Accurate assembly torque

- No shortcut in electrical wiring

These things are invisible in photos — but show up after 2–3 years of work.

12. Choosing the Right Mini Excavator for Your Annual Workload

Simple rule:

- Under 500 hours/year → Entry-level is OK

- 600–1,200 hours/year → Balanced, well-tested machine

- 1,200+ hours/year → Focus on hydraulics and cooling first

Buyers planning heavy use should always ask:

“How many hours do your export machines typically reach?”

13. Where Nicosail Fits In

Some factories focus on ultra-low prices.

Others focus only on premium specs.

Brands like Nicosail sit in the middle:

- Not over-designed

- Not under-built

- Focused on export reliability

This kind of positioning works well for buyers aiming at:

- 800–1,500 working hours per year

- Stable resale value

- Fewer headaches during peak season

It’s not about advertising — it’s about matching machine life to real working hours.

14. FAQ – Real Questions Buyers Always Ask

Q1: Is 1,000 hours per year too much for a mini excavator?

No. For a well-built 1–3 ton machine, 1,000 hours/year is normal.

Q2: How many total hours should a China mini excavator last?

A decent one should reach 5,000–8,000 hours with proper maintenance.

Q3: Is it better to buy cheaper and replace sooner?

Only if downtime doesn’t matter. Most professionals prefer stable uptime.

Q4: Can one machine handle both farm and construction work?

Yes, if attachments and hydraulics are matched correctly.

Q5: Is resale value affected by yearly hours?

Yes — buyers prefer machines with steady usage, not extreme overuse or very low use.

15. Final Summary: The Short Answer

So, how many hours per year should a 1–3 ton China mini excavator work to be profitable?

👉 Minimum: 300–400 hours/year

👉 Best ROI: 700–1,200 hours/year

👉 Heavy use (acceptable): 1,500+ hours/year with a solid machine

If the working hours match the machine quality,

profit comes naturally — without stress, without surprises.

That’s the real logic behind mini excavator profitability.