1. Why So Many Buyers Are Looking at Chinese Mini Excavators

In Europe, North America, and Australia, one thing is obvious:

equipment prices from traditional brands keep going up.

For distributors and rental companies, that creates pressure:

- Margins are shrinking

- Customers want lower prices

- Fleet expansion is expensive

That’s exactly why Chinese mini excavators are getting so much attention.

Ten years ago, many buyers wouldn’t even consider them.

Today, Chinese machines are:

- Running on European job sites

- Working daily on farms and landscaping projects

- Being rebranded and sold by importers

But here’s the key question:

Are they actually right for your business model — or just cheap on paper?

2. What “Chinese Mini Excavator” Really Means Today

A common mistake is thinking all Chinese mini excavators are the same.

They’re not.

In China, there are:

- Small workshops assembling machines by hand

- Mid-level factories with partial production lines

- Full-scale factories with welding robots, testing stations, and export experience

Some machines are built to:

- Pass EU & North American inspections

- Run 2,000+ hours without major issues

Others are built to:

- Look good in photos

- Be as cheap as possible

- Ship fast, with no long-term plan

When buyers say “Chinese machines are risky”, most of the time they mean:

They bought from the wrong factory, not the wrong country.

3. The Biggest Advantages (Pros) — Where Chinese Machines Shine

3.1 Price Advantage That Actually Matters

Let’s be honest — price is the first reason buyers look at China.

Compared with Japanese or European brands:

- Initial purchase cost can be 30–50% lower

- Container-level orders reduce unit cost further

- Rebranding potential increases resale margins

For distributors, this means:

- More room for profit

- Flexible pricing strategies

- Faster market entry

But price alone is not the real advantage.

3.2 Simple Design = Easier Maintenance

Most Chinese mini excavators use:

- Mechanical structures instead of complex electronics

- Proven hydraulic layouts

- Easy-to-access components

That matters because:

- Rental customers abuse machines

- Farm users don’t want complicated diagnostics

- Overseas service networks are limited

Simple machines:

- Break less

- Cost less to repair

- Keep customers happier

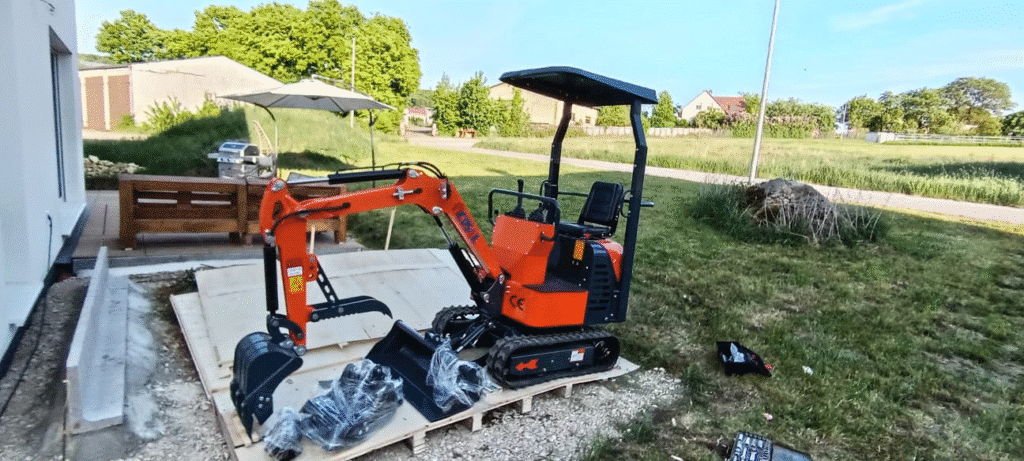

3.3 Customization That Western Brands Don’t Offer

Chinese factories are flexible.

Buyers can request:

- Different engines (Kubota, Yanmar, or cost-optimized options)

- Joystick patterns

- Canopies or enclosed cabins

- Custom colors and decals

- Reinforced arms or undercarriages

This is why many importers:

- Rebrand machines

- Build private-label equipment lines

- Create “local brands” for their markets

Western OEMs rarely allow this.

3.4 Faster Production for Bulk Orders

For distributors and rental companies, timing matters.

Chinese factories often offer:

- Shorter lead times for container orders

- Scalable production lines

- Flexible scheduling during peak seasons

That helps avoid:

- Missing spring or summer sales windows

- Losing customers due to long waits

4. The Real Disadvantages (Cons) — Where Buyers Get Burned

Now let’s talk about the uncomfortable part.

4.1 Quality Inconsistency Between Suppliers

This is the biggest risk.

Two machines may:

- Look identical

- Use similar parts

- Have very different reliability

Common problems from low-end suppliers:

- Poor welding quality

- Cheap hoses that crack early

- Electrical issues after a few months

- Weak pins and bushings

Buyers who skip factory audits often pay for it later.

4.2 Certification Problems Can Kill a Deal

Some suppliers claim:

- “CE approved”

- “EPA compliant”

But what they really have is:

- Old certificates

- Incomplete documentation

- Certificates issued for different models

For importers, this can mean:

- Customs delays

- Machines stuck at port

- Legal risks

Certification fraud is real — and expensive.

4.3 After-Sales Support Depends on the Factory

A machine is only as good as:

- Spare parts availability

- Technical response speed

- Willingness to take responsibility

Some factories disappear after shipment.

Others treat after-sales like a long-term partnership.

This difference is not visible in Alibaba photos.

4.4 Resale Value Is Brand-Dependent

Let’s be clear:

- Unknown machines are harder to resell

- Buyers trust brands, even private labels

That’s why smart importers:

- Choose stable factories

- Build consistent product lines

- Invest in quality from the start

5. Cost vs Value: Cheap Is Not the Same as Profitable

Many buyers focus on FOB price.

Experienced buyers focus on:

- Total landed cost

- Failure rate

- Warranty claims

- Customer complaints

- Reputation damage

A machine that’s:

- $1,500 cheaper

- But causes downtime

- And angry customers

Is not cheaper in the real world.

6. Quality Control: The Difference Between Factories

High-quality Chinese factories usually have:

- Standardized welding jigs

- Hydraulic pressure testing

- Engine run-in testing

- Final inspection checklists

Low-end suppliers usually:

- Assemble by eye

- Skip pressure testing

- Ship without full inspection

That difference shows up after 300–500 working hours.

7. Certifications, Compliance, and Risk Control

For EU, US, and Australia markets, buyers should confirm:

- CE conformity (real, model-specific)

- EPA / Euro engine compliance

- Noise and safety standards

Smart buyers:

- Verify certificates before payment

- Match serial numbers

- Keep compliance records

This is where experienced export factories stand out.

8. Spare Parts, After-Sales, and Long-Term Ownership

Good factories:

- Stock spare parts for years

- Use common components

- Provide manuals and diagrams

Bad ones:

- Change designs frequently

- Can’t supply old parts

- Blame customers for failures

For rental fleets, this is critical.

9. Who Should Buy a Chinese Mini Excavator (And Who Shouldn’t)

Good Fit If You Are:

- A distributor building a private label

- A rental company focused on ROI

- A buyer who inspects factories

- A business with service capability

Not a Good Fit If You:

- Expect premium-brand resale value

- Don’t want to manage suppliers

- Need ultra-high-tech features

10. How Smart Importers Reduce Risk When Buying from China

Successful buyers usually:

- Visit factories or hire inspectors

- Start with small trial orders

- Test machines locally

- Lock specifications before scaling

They treat supplier selection as a strategy, not a transaction.

11. Why Some Buyers Quietly Switch to Brands Like Nicosail

Some buyers don’t want:

- The risk of random suppliers

- The hassle of chasing certificates

- Inconsistent quality

They prefer factories that:

- Focus on mini excavators only

- Have stable production lines

- Export mainly to Europe and North America

- Understand distributor concerns

That’s why brands like Nicosail often show up in long-term partnerships — not because they are the cheapest, but because they are predictable.

12. FAQ — Straight Answers Buyers Care About

Q1: Are Chinese mini excavators reliable?

Yes — if they come from the right factory. No — if they don’t.

Q2: Can they match Japanese brands?

For light to medium duty, many can. For extreme, 24/7 abuse, brand choice matters more.

Q3: Is certification a real risk?

Yes. Always verify documents before shipment.

Q4: Are spare parts a problem?

Only with unstable suppliers. Good factories plan parts support.

Q5: Is rebranding common?

Very. Many “local brands” are built on Chinese machines.

13. Final Summary: Is It Right for Your Business?

A Chinese mini excavator is not automatically a good or bad choice.

It depends on:

- Your business model

- Your risk tolerance

- Your supplier selection

For many distributors and rental companies, Chinese machines:

- Lower entry cost

- Improve margins

- Offer flexibility

But success comes from:

- Choosing the right factory

- Looking beyond price

- Treating machines as long-term assets

When done right, a Chinese mini excavator isn’t a compromise —

it’s a smart business decision.