Chinese mini excavators have become one of the most popular items in the global compact equipment business. Distributors, rental companies, and importers from Europe, North America, and Australia are all looking at China to build their own brands and margins.

But when it comes to wholesale pricing and MOQ (Minimum Order Quantity), things often get confusing:

- Why does one factory offer a 1-ton mini excavator at USD 3,800 and another at USD 6,500?

- Why does one supplier accept 1 unit and another insists on 4, 6, or even 10 units?

- When exactly does the “cheap” quote become an expensive mistake?

This guide explains how pricing and MOQ really work on the Chinese side, using the logic and habits of actual factories. It is written for B2B buyers: dealers, importers, rental fleets, and brand owners.

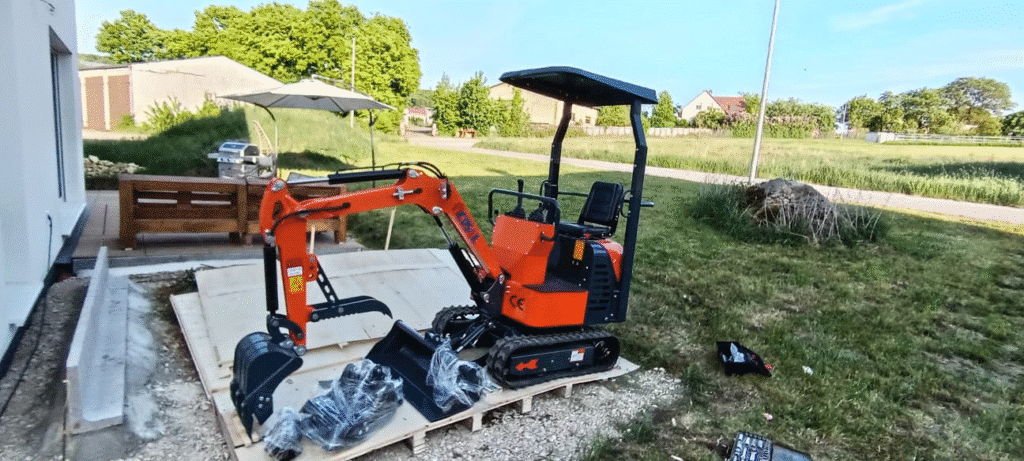

Nicosail will be used as a friendly example in some parts, because it is a typical Chinese factory with experience in mini excavator manufacturing and export. The goal is not advertising, but to show how a serious factory tends to structure offers and conditions.

1. Why so many dealers choose Chinese mini excavators for wholesale

For B2B buyers, the logic is simple:

- Mini excavators are easy to sell in construction, landscaping, and agriculture.

- Small machines have faster rotation than big equipment.

- Chinese factories offer flexible customization and attractive margins.

Wholesale buyers usually look for:

- A machine that can be rebranded with their own logo.

- A price that still leaves room for 20–60% gross margin in the local market.

- Reliable quality that will not destroy reputation after one season.

- A factory that understands certification and export paperwork.

This is exactly where mid-level Chinese manufacturers, such as Nicosail and similar factories, have built their position: not the cheapest in the market, but balanced in price, reliability, and flexibility.

2. How Chinese mini excavator pricing really works

Pricing is not random. On the factory side, every USD difference usually comes from a choice in:

- Engine

- Hydraulic components

- Steel and structure

- Attachments and options

- Production scale and process control

Understanding this logic makes it easier to judge whether a quote is reasonable or not.

2.1 Key cost drivers

1) Engine brand and emission level

- Chinese local engines (Changchai, Koop, etc.)

- Lower cost

- Suitable for some markets in Asia, Africa, Latin America (depending on regulations)

- Branded engines (Kubota, Yanmar, Perkins, etc.)

- Higher cost

- Required for Europe / North America because of EU Stage V / EPA Tier 4f

- Engine alone can add several hundred to over one thousand dollars to the machine price.

2) Hydraulic system

- Pump (gear vs piston), main control valve, swing/track motors, cylinders.

- Well-known brands (KYB, Eaton, Nabtesco, etc.) usually mean:

- Smoother operation

- Better durability

- Higher cost

Cheaper components sometimes look similar on the outside but use different seals, machining, and quality standards. This shows later in oil leakage, jerky motion, shorter lifespan.

3) Steel structure and welding

- Thickness of boom, arm, chassis plates.

- Quality of welding (robot welding vs hand welding, correct welding procedures, stress point treatment).

- Design details around high-stress areas (for example, boom base, arm root, bucket linkage).

These things are not always obvious in photos, but they directly affect crack resistance and long-term reliability.

4) Attachments and configuration

- Standard bucket only, or bucket + ripper + auger + quick hitch?

- Canopy or closed cabin?

- Hydraulic pilot control or mechanical levers?

- Rubber track quality level?

Each of these items adds cost. A very low base price often means a very basic configuration.

5) Production scale and management

Factories with stable monthly volume can:

- Purchase engines and hydraulics at better prices.

- Standardize processes and reduce rework.

- Offer more stable quality and lead time.

Smaller workshops may quote very aggressively but struggle with cycles, stability, and warranty.

2.2 Typical price ranges by size

Real prices vary, but for reference (FOB China, basic configurations):

- 0.8–1.0 ton micro excavator

- With local Chinese engine, simple configuration: often in the lower price band.

- With branded engine and better hydraulics: mid to higher band.

- 1.5–2.0 ton mini excavator

- Very popular for rental and entry-level construction.

- Price difference here mainly comes from engine brand, valve/pump brand, cabin vs canopy.

- 2.5–3.5 ton mini excavator

- Closer to “professional” use, more stress on structure.

- Usually uses better components and stronger frames.

- Higher unit price but often still very attractive compared to local OEM brands.

A warning signal: If one quote is much lower than most others at the same specification level, it usually means hidden downgrades somewhere in engine, hydraulics, steel, or internal parts. This is where many new importers get burned.

2.3 What is included — and what is not

When comparing prices, always check:

- Included:

- Standard bucket?

- Hydraulic oil and fuel?

- Basic tools and user manual?

- Standard paint and decals?

- Not always included:

- Additional buckets, augers, rippers, grapples

- Quick coupler

- Cabin with heater/AC

- Custom color or logo

- Spare parts package

- Extended warranty

A clear quotation separates standard configuration and optional extras. This makes total cost much easier to calculate.

3. Understanding MOQ (Minimum Order Quantity) in China

MOQ is not only about “how many units” the factory wants to sell. It is also about:

- Production planning

- Paint and branding setup

- Container optimization

- Risk control on the supplier side

3.1 Common MOQ patterns

For mini excavators, typical MOQ patterns look like this:

- 1 unit

- Often accepted as a sample order.

- Sometimes price is a bit higher than for large batches.

- Good for testing local market and checking quality.

- 2–3 units

- Often the MOQ for mixed models in one shipment for new customers.

- Some factories accept 1 unit each of 2–3 different models to help dealers test the range.

- 4–6 units

- Common MOQ to fill a 20GP container efficiently, depending on size.

- Many factories structure discounts at this level.

- 10+ units

- Usually for dealers with running business.

- Better pricing, more customization options, possible support on marketing materials.

A factory like Nicosail typically offers flexible MOQs for first-time cooperation (including 1-unit samples), then encourages container-based quantities once trust is built.

3.2 Customization and MOQ

Every extra customization step affects MOQ:

- Custom paint color

- If the factory must change paint setup, it prefers more units per color to reduce cost.

- Some suppliers require minimum 2–4 units per color.

- Own logo and brand decals

- Simple sticker logo: usually available even for 1 unit.

- Complex 3D logo or metal plates: may require a minimum batch to justify mould or setup costs.

- Special engine or hydraulic brand

- Import engines and special components are often ordered in batches.

- Factory may ask for higher MOQ or longer lead time for these “non-standard” versions.

- Unique specifications (different boom, extra counterweight, special controls)

- These changes affect design, welding jigs, and testing.

- Factories prefer higher MOQ or a development agreement for such cases.

3.3 Smart ways to meet MOQ without overstocking

Many importers want the benefits of wholesale pricing but fear dead stock. Some practical strategies:

- Mix models in one container

- Example: combine 1-ton, 1.8-ton, and 2.5-ton units.

- This reduces risk on any single model.

- Same color and brand, different sizes

- Keep paint scheme and logo unified to keep MOQ lower and cost down, while offering a full range to customers.

- Start with 1–3 units, then plan a container order

- Use the first small shipment to test market, check feedback, and refine specifications.

- Then move to container quantities with more confidence.

- Discuss phased orders

- Some factories agree to a schedule, for example: 4 units now, 4 units next season at a similar price level.

A structured discussion with the factory about MOQ, rather than only asking “Can MOQ be 1?”, usually leads to more favorable and realistic terms.

4. Hidden costs many buyers forget

The unit price is just one part of the total cost. For importers and dealers, the real number comes after adding all landed costs.

4.1 Shipping and Incoterms

- EXW (Ex Works)

- Buyer arranges everything from factory door to final destination.

- Most flexible, but requires logistics knowledge.

- FOB (Free On Board)

- Factory delivers to the loading port and handles export customs.

- Very common for mini excavator exports from China.

- CIF / CFR

- Supplier arranges ocean freight; buyer still handles local import charges.

- Can be convenient, but always double-check what is actually included.

Ocean freight, insurance, port charges, local trucking, and customs clearance all add up. In some cases, space utilization of the container can influence cost per machine more than a small discount in unit price.

4.2 Compliance and certificates

For Europe, North America, and some other markets, compliance has real costs:

- CE marking for the EU

- EPA engine compliance for the US

- Stability and safety tests, sometimes ROPS/FOPS structures

- Noise, hydraulic, and electrical safety requirements

Serious factories include these compliance costs in the price and can show real test reports and certificates. Unreliable suppliers may:

- Offer fake or misused certificates

- Use an engine without proper emission compliance

- Put the buyer at risk during customs or later inspections

For B2B buyers, it is better to pay slightly higher for a machine that passes customs and inspections smoothly, than to risk seizure or penalties.

4.3 After-sales and spare parts costs

Dealers must also consider:

- Basic spare parts stock (filters, seals, pins, bushings, hoses).

- Warranty repairs within 1–2 years.

- Technician time, travel, and workshop costs.

Some factories, including Nicosail and similar brands, prepare spare parts lists and can supply extra parts with the machines in the same container. This helps reduce future freight costs and improves service speed.

5. How to read a Chinese supplier’s quotation sheet

A typical mini excavator quotation usually includes:

- Model number and description

- Engine brand and power

- Operating weight, bucket capacity

- Standard configuration list

- Optional configuration and price

- Unit price (EXW/FOB/CIF)

- MOQ and lead time

- Payment terms

Points that deserve special attention:

- Engine and hydraulics clearly named

- “Japanese engine” or “famous brand” is not clear enough.

- The quotation should state exact engine model and main hydraulic brand.

- Standard configuration detail

- Items like canopy, work lights, auxiliary hydraulic line, adjustable seat, indicators.

- Lack of detail often means misunderstandings later.

- Options priced separately

- Ideally, cash values are listed for each attachment or upgrade.

- This helps dealers design their own packages for customers.

- Lead time by quantity

- Very short lead time for large quantities can be unrealistic.

- A factory with stable processes will give a reasonable and reliable time frame.

- Payment terms

- Typical terms: 30% deposit, 70% balance before shipment.

- Some suppliers provide flexibility for long-term partners, but this usually comes after trust is built.

6. Realistic negotiation strategies on price and MOQ

Negotiation is expected in B2B trade, but certain approaches work better in China’s machinery industry.

1) Negotiate based on total order value, not only unit price

Suppliers think in terms of:

- Total value of the order

- Repetition of future orders

- Stability of cooperation

A buyer who clearly explains a plan for continuous orders may get better terms even at a slightly smaller first shipment.

2) Use container optimization as a negotiation point

If a 20GP container can fit, for example, 4–6 units of a specific size, this can be a natural MOQ point for better pricing. Factories like to standardize on such breakpoints.

3) Be realistic about component brands

If the requirement is:

- Premium engine (Kubota/Yanmar/Perkins)

- Branded hydraulics

- Cabin with heater/AC

- Custom color

- Full attachments package

…then the price cannot be at the same level as a basic spec competitor. Pushing too hard often leads to hidden downgrades.

4) Ask for value, not only discounts

Instead of only asking: “Can the price be lower?”, it often works better to discuss:

- Extended warranty

- Extra filters and wear parts included

- Free branding and color customization

- Training videos or marketing materials

Serious factories are more open to providing extra value than to cutting price to unsafe levels.

7. Quality control checklist before placing a big order

Before committing to a large wholesale order, B2B buyers usually follow some checklist.

7.1 Factory background and certifications

- Legal factory with export license

- Real production lines, not just a trading office

- CE, ISO, and other relevant certifications

- Stable export history to similar markets

Nicosail, for example, operates as a factory with multiple production lines for mini excavators and loaders, which is typical of mid-sized Chinese manufacturers aimed at long-term export.

7.2 Technical checkpoints on the machine

Important items to verify, either through on-site visit or third-party inspection:

- Engine: starting, noise level, vibration, emission label

- Hydraulics: smoothness of boom/arm/swing/travel motion, leakage signs

- Welding: look especially around boom roots, arm joints, bucket ears, chassis nodes

- Hose routing: should avoid sharp bends, friction points, and tight stretches

- Electrical harness: secure fixing, protection sleeves, clean routing

- Greasing points: easy access, well-marked

- Undercarriage: track tension, roller quality, idler and sprocket finish

These details reveal whether the factory focuses only on appearance or also on invisible reliability.

7.3 Pre-shipment inspection tips

Before shipping, it is wise to:

- Confirm machine serial numbers and model labels.

- Check that the configuration matches the PI (proforma invoice).

- Verify brand decals and paint match the agreed design.

- Confirm that tools, manuals, and spare parts are placed correctly.

Many dealers use third-party inspection companies, but the most effective control comes from clear, written inspection points agreed with the factory in advance.

8. Example: How a brand like Nicosail structures wholesale pricing & MOQ

Nicosail can be used as a practical example of how a mid-sized Chinese factory handles wholesale deals.

Typical approach:

- Product range: mini excavators from around 0.8 ton to 6 ton, plus compact tracked loaders and skid steer loaders.

- Target markets: Europe, North America, Australia, and other regions requiring more attention to emissions and safety.

- Wholesale pricing:

- Based on engine brand (Chinese or international), emissions level, and configuration.

- Discounts or better terms for container-based orders and repeat buyers.

As for MOQ:

- For new customers, often 1 unit is accepted as a trial order, especially if the buyer is building a new brand or testing a new market.

- For serious distributors, MOQ usually follows container logic:

- 1×20GP: often 4–6 units depending on model.

- 1×40HQ: more units with better freight efficiency.

- Custom paint and branding are usually optimized when at least a few units share the same scheme.

Nicosail and similar factories also tend to support dealers with:

- Spare parts packages shipped together with the machines.

- Layout support for logos and color schemes.

- Basic operation and maintenance videos for the end users.

For B2B buyers looking for a long-term partner rather than a one-time shipment, a factory of this type usually offers a more stable base than very small workshops or purely trading companies.

9. FAQ: Wholesale Chinese mini excavators

Q1. What is a reasonable MOQ for wholesale Chinese mini excavators?

For most factories, 1 unit can be accepted as a sample. For serious wholesale, MOQ usually aligns with container loading: around 4–6 units for a 20GP and more for a 40HQ. For custom colors and branding, factories often prefer at least 2–4 units per color.

Q2. How big is the price difference between Chinese engine and branded engine?

The difference can be several hundred to over one thousand dollars per unit, depending on engine size and emission level. However, the choice also affects customs clearance, local regulations, and resale value in high-level markets.

Q3. Why do some suppliers offer very low prices? Is it safe to buy?

Very low prices often come from downgrades in:

- Engine (unbranded or non-compliant engines)

- Hydraulics (low-cost pumps, valves, motors)

- Steel thickness and welding quality

- Lack of real testing and inspection

This might work for extremely low-end markets, but for dealers in Europe, North America, and similar regions, it usually means higher warranty and reputation risks.

Q4. Can different models be mixed in one container?

Yes. Many factories encourage mixing, such as 1-ton, 1.8-ton, and 2.5-ton units in the same container. This helps dealers test market response across different sizes and reduces risk.

Q5. How to avoid certificate fraud (fake CE, etc.)?

Several steps help:

- Request copies of certificates and check whether the manufacturer name matches the contract.

- Ask for test reports from recognized labs.

- If possible, use a third-party verification service.

- Focus on factories with a real export track record rather than very new or unknown suppliers.

Brands like Nicosail, which regularly export to demanding markets, usually have more complete documentation and experience with inspections.

Q6. Are spare parts easy to get after buying from China?

For common wear parts (filters, pins, bushings, seals), good factories keep stable supply. Dealers can order starter spare parts kits with the machines to cover the first year or two. For engines and main hydraulics, most branded components have global support networks.

Q7. How long is the normal warranty for wholesale mini excavators from China?

A typical structure is:

- 1 year for the whole machine

- Longer terms for engine (depending on engine brand’s own warranty)

- Exclusions for wear parts like filters, hoses, seals, and tracks

Some factories are open to extended warranty for key markets if pricing and service arrangements are discussed in advance.

Q8. Is it better to buy from a trading company or directly from a factory?

Both models can work, but for building a long-term brand, direct cooperation with a stable factory often gives:

- Better control over specifications and quality

- More competitive pricing in the long run

- Faster feedback on production and technical issues

Factories like Nicosail focus on direct partnerships with distributors and importers, while still understanding that some buyers may prefer to start through trading channels.

10. Summary: Key takeaways for B2B buyers

When looking at wholesale Chinese mini excavators, pricing and MOQ are only the visible part of the story. The real game is in:

- The engine and hydraulic choices behind the numbers

- The steel structure and welding quality that determines long-term durability

- The way MOQ, container loading, and customization are balanced

- The hidden costs of freight, compliance, and after-sales

A slightly higher unit price from a serious factory often becomes cheaper in the long run than a rock-bottom deal from an unstable supplier.

For distributors, rental fleets, and importers in Europe, North America, and similar markets, it is usually safer to:

- Start with 1–3 units from a reliable factory to test both quality and market reaction.

- Move to container-based MOQs once specifications and branding are clear.

- Work with a partner that understands certification, documentation, and spare parts supply.

Brands like Nicosail represent a group of Chinese manufacturers that combine:

- Factory-level control over production

- Experience exporting to high-demand markets

- Flexibility in customization and MOQ

Choosing a supplier in this category helps B2B buyers build their own brands and margins with fewer surprises and a more predictable long-term business.