Chinese mini excavator OEM projects can be very profitable… or very painful.

Some buyers end up with strong private-label machines that sell for years.

Others get stuck with delays, warranty nightmares, and certifications that “look” real but are not.

The difference usually comes down to how the OEM contract is negotiated.

This guide is written for B2B buyers, dealers, rental companies and importers who want to put their own brand on Chinese mini excavators and sell in Europe, North America, Australia, or other demanding markets.

It walks through the main points to negotiate, how to talk to Chinese factories, and how to protect both profit and reputation—using real factory logic, not just theory.

Nicosail is used as a reference example of a Chinese factory that offers OEM mini excavators, but the principles apply to any supplier.

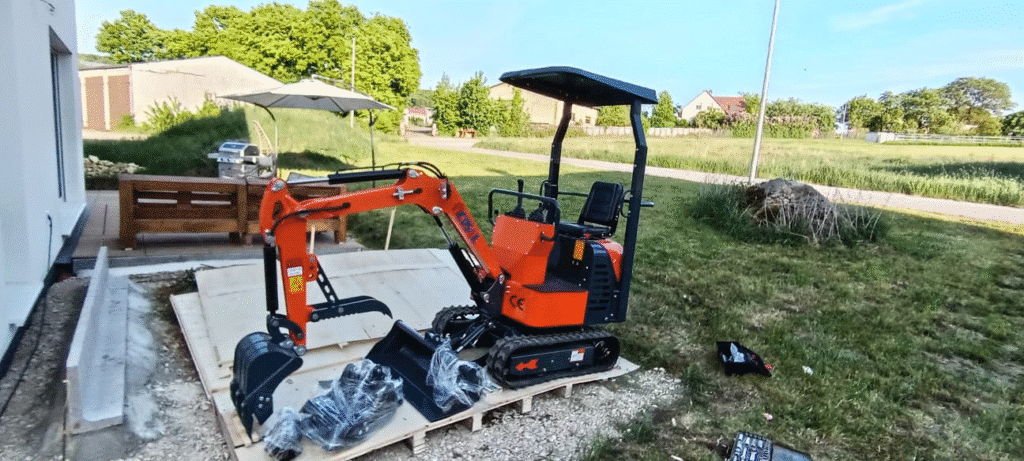

What an OEM Mini Excavator Deal Really Means

Before jumping into price and logo design, it helps to clarify what “OEM” actually means in the Chinese construction machinery world.

OEM (Original Equipment Manufacturer) in this context usually means:

- The factory designs and produces the mini excavator platform.

- The buyer provides brand name, colors, decals, sometimes small configuration changes.

- The machines are sold under the buyer’s brand in the local market.

Sometimes there is also ODM (Original Design Manufacturing):

- The buyer wants more technical changes: different boom geometry, new cab design, special hydraulics, or attachments package.

- This means more engineering work, longer lead time, and usually tooling costs.

For most small and medium dealers/importers, the realistic setup is:

- Standard factory platform (for example 1.0T–2.0T mini excavator from a brand like Nicosail).

- Custom color, logo, decals, maybe joystick pattern, seat, lighting, and some hydraulic options.

- Compliance for CE, EPA Tier 4/Stage V where needed.

The more this is all clearly defined on paper, the smoother the cooperation.

Preparation Before Talking Numbers

Strong negotiation starts before the first price request.

1. Define the business model and positioning

Before approaching factories, the buyer should be able to answer:

- Target market? (EU, UK, Canada, USA, Australia, etc.)

- Target customer? (Rental, small contractors, farmers, landscapers, DIY)

- Machines mainly used for? (Landscaping, trenching, demolition, farm work)

- Price segment? (Budget, mid-range, or premium within the local market)

This will drive:

- Engine choice: Chinese brand engine vs Kubota/Yanmar/Briggs where needed.

- Hydraulic system level: basic gear pump vs higher-end valves and pumps.

- Features: canopy vs cab, proportional auxiliary, quick coupler, etc.

Going to a factory with unclear positioning often leads to:

- Over-spec: machine too expensive for local customers.

- Under-spec: machine too cheap, unreliable, and damaging to the brand.

2. Decide on volume scenarios

Chinese factories think in terms of volume vs. complexity:

- Small volume + heavy customization = high unit cost, low interest.

- Clear volume plan + reasonable customization = better price and attention.

Helpful preparation:

- Estimate first year volume (for example 30–50 units).

- Estimate three-year volume (for example 150–200 units).

- Decide first order size (pilot order to test market, e.g. 5–10 units).

This information allows the factory to:

- Offer better long-term pricing and annual rebates.

- Justify investments in tooling, molds, jigs, and special fixtures.

Many serious factories like Nicosail respond better when there is a simple, realistic 1–3 year plan instead of only a “what’s the best price for 1 unit?” chat.

3. Understand basic cost drivers

Even without deep technical knowledge, buyers benefit from understanding where the money goes in a mini excavator:

- Steel structure (chassis, boom, arm, attachments)

- Engine and cooling system

- Hydraulic pump, valve, motors, hoses, cylinders

- Electrical system and wiring

- Undercarriage (tracks, rollers, sprockets, idlers)

- Labor, welding, painting, testing

- Packaging and inland transportation to port

This helps avoid unrealistic demands such as:

- Requesting a Kubota engine, premium hydraulics, plus cab and A/C at the price level of an entry-level Chinese engine machine.

- Pushing price too low so the factory has no margin and silently cuts corners.

Reasonable negotiation understands that some options directly raise cost and must be reflected in pricing.

Key Contract Terms to Negotiate

Product Specifications and Options

A surprising amount of disputes come from “misunderstanding” of the technical configuration. To avoid this, the contract should include a clear and detailed spec sheet, such as:

- Operating weight (with which attachment and which configuration)

- Engine brand, model, emission standard

- Pump type (gear or piston), main valve brand

- Auxiliary hydraulic lines (single/double, flow rate, control method)

- Undercarriage type (fixed/expandable track, rubber/steel track)

- Cab or canopy, safety features (ROPS/FOPS where applicable)

- Standard bucket size and included attachments

For OEM buyers, also specify:

- Color code (e.g. RAL code for yellow, black, gray)

- Logo / decals position and size

- Serial plate content format (brand, model, serial number, year)

Factories like Nicosail usually have a standard spec form that can be adapted with OEM fields. This spec sheet should be attached to the contract and referenced by contract number.

Quality Standards and Testing

Talking about “high quality” is meaningless without concrete items. The contract should address:

- Incoming material control: key components must come from agreed brands and suppliers.

- Welding and painting: describe basic standards (such as no visible slag, no unpainted zones, thickness ranges if needed).

- Functional testing: each machine to be test-run with all functions (travel, swing, boom, arm, bucket, auxiliary, safety devices).

- Leak-free requirement: no visible hydraulic oil leaks at shipment.

- Load test: for some buyers, a simple load or pressure test protocol is agreed.

A practical approach is:

- Attach the factory’s test checklist to the contract.

- Confirm that each unit will be tested and the checklist kept for records.

Allowing a bit more price for proper QC is usually cheaper than handling one big warranty wave in a foreign country.

Branding, Design, and Tooling

OEM contracts must clarify:

- Who designs the decals and logo artwork.

- Who owns the tooling (molds for plastic covers, metal fixtures for special parts, stamping dies, etc.).

- Who pays for any new tooling, and how costs are amortized.

Typical structures:

- For simple OEM (painting, decals): no tooling cost, just one-time small design fee or free.

- For new covers or special counterweights: there may be a tooling charge, but ownership and usage rights should be clearly defined.

A fair clause often looks like:

- Tooling belongs to the buyer after full payment.

- Tooling is stored and used only for the buyer’s orders.

- If the cooperation ends, the buyer can take over or scrap tooling (with a clear procedure and costs).

Factories that seriously do OEM work, such as Nicosail, usually already have internal rules for tooling control and can explain them during negotiation.

Price, Payment Terms, and Incoterms

Pricing discussions should cover more than just the number on the proforma invoice.

Key points to negotiate:

- Price level and currency: EXW, FOB, or CIF, in USD/EUR.

- Payment term: most common is 30% deposit, 70% before shipment (T/T). For larger, longer-term customers, partial LC can be considered.

- Incoterms: FOB Chinese port (Qingdao, Shanghai, Ningbo, etc.), CIF destination port, or DAP in some cases.

Useful ideas:

- Instead of asking for “lowest possible price” for the first small order, negotiate a starter price and then a better price for 2nd and 3rd order based on volume.

- Build in a price review mechanism in case of major changes in steel or engine costs.

For example:

- Price valid for 3–6 months.

- If raw material index increases above a certain percentage, both sides renegotiate in good faith.

MOQ, Lead Time, and Delivery Plan

Negotiation should make clear:

- Minimum order quantity (MOQ) per model / per configuration.

- Standard lead time (for example 25–35 days after deposit for first order, 20–30 days for repeat orders).

- Handling of peak season (often around March–June before the northern hemisphere busy season).

To avoid missing peak sales:

- Include in the contract an annual forecast schedule (for example Q1, Q2, Q3, Q4 estimated quantities).

- Lock in production slots if volumes justify it.

Some factories like Nicosail can pre-reserve key components (engines, valves, tracks) based on forecast, which reduces the risk of delays, but only if the buyer shares realistic plans.

Certificates and Compliance

This is crucial for Europe, North America, Australia, and sometimes UK-specific requirements.

The contract should clearly define:

- Which certificates are required: CE, UKCA, EPA, noise labels, etc.

- Whether the certificates are for the factory’s brand model or also cover the OEM brand.

- Who handles technical files, manuals, and risk assessment.

- Whether third-party Notified Body involvement is needed.

To avoid certificate problems:

- Ask for copies of existing certificates and cross-check factory name, address, and machine designation.

- State in the contract that valid certification and compliance are required conditions for shipment.

Reliable manufacturers like Nicosail are used to EU and US requirements and can support with labelled plates, manuals in English, and basic risk assessment documents.

Warranty, Spare Parts, and After-Sales Support

For long-term business, these points matter more than saving 50 USD per unit.

Negotiation points:

- Warranty period: commonly 12 months after arrival or 1000 working hours, whichever comes first (for whole machine). Key components like engines may follow their own warranty terms.

- Warranty scope: define what is covered (manufacturing defects) and what is not (abuse, lack of maintenance, wear parts).

- Spare parts support: availability period (for example 5–10 years) and parts pricing policy.

- Whether the buyer will stock key spare parts locally, and if the factory can offer a parts package in the first order.

A good contract might include:

- A recommended spare parts list for the first 20–50 machines (filters, belts, pins, seals, small cylinders, switches).

- Agreement that the factory will provide technical support by email/chat/video in case of problems.

Factories with OEM experience, such as Nicosail, usually already have standard spare parts lists and troubleshooting manuals that can be slightly branded for the buyer.

Confidentiality and IP Protection

Even if a mini excavator is not a high-tech secret weapon, branding and market data are still important assets.

The OEM contract should include:

- A simple non-disclosure clause regarding drawings, pricing, customer lists and sales data.

- Clear statement that the factory cannot use the buyer’s brand for other customers or marketing without written consent.

- If special design is involved, basic IP clauses about using those features only for this buyer.

While it is hard to fully “police” this internationally, a written contract and cooperation with a reputable factory (such as a stable brand like Nicosail) still gives much better protection than loose email promises.

Negotiation Tactics That Work with Chinese Factories

Many problems are not technical but communication style. A few practical principles help a lot.

Focus on long-term cooperation, not one deal

Most serious factories prioritize:

- Stable partners

- Predictable volume

- Fewer models but deeper cooperation

When the buyer’s communication always focuses only on “this one container” and “lowest price”, factories tend to:

- Cut corners quietly

- Give low priority in production planning

- Be less flexible when problems appear

Presenting a 3-year plan, even with modest numbers, sends a strong signal and usually leads to better terms.

Share target price and target spec honestly

Instead of asking “best price?” with no context, it helps to say:

- Target retail price in local market

- Competitor brands considered

- Acceptable level of specification

Factories then can:

- Propose alternative configurations to hit cost targets (for example, Chinese engine to start, upgrade to Kubota when volume grows).

- Suggest standard colors and parts that are easier and cheaper to produce.

Nicosail, for example, often proposes several “levels” of the same tonnage: a basic rental version, a mid-range contractor version, and a higher-spec version for tough users. That kind of tiered approach only works if the buyer shares realistic expectations.

Negotiate package deals, not single items

Instead of fighting over every small optional item, it often works better to:

- Bundle a full configuration and negotiate the package price.

- Discuss annual rebate or bonus for reaching certain volume.

This gives the factory more room to manage internal costs, while still giving the buyer competitive pricing.

Keep emotions low, data and facts high

When something goes wrong (delay, defect, document problem), the negotiation should:

- Stick to facts, photos, videos, serial numbers.

- Refer to the original contract and inspection reports.

- Focus on a solution (rework, spare parts dispatch, discount in next order).

Chinese factories generally respond much better to clear, calm problem analysis than to angry or vague complaints. OEM-friendly factories like Nicosail are used to structured feedback and will usually cooperate if the issue is real and documented.

Red Flags to Watch Out For

Not every “factory” is equal, and not every offer is safe. Some warning signs:

- Unrealistically low prices

- If a quote is much lower than established factories for similar specs, something is likely missing: cheaper steel, weaker structure, no proper testing, or no real warranty behind it.

- Very short promised lead time for complex machines

- When everyone quotes 30 days and one supplier offers 10–15 days for custom OEM machines, either capacity is empty for a reason or promises are not realistic.

- Unclear identity (trader vs factory)

- No real factory address, no workshop photos, no production line details.

- Always changing contact persons and signatures.

- Certificates seen only as a “PDF attachment” with strange details

- CE documentation where factory name and address do not match the supplier being negotiated with.

- No technical files, no test data, only a pretty certificate picture.

- Unwillingness to sign a bilingual contract

- Serious factories are used to counter-signed Chinese–English contracts. Refusal to formalize terms is a bad sign.

Factories like Nicosail usually welcome factory visits, video tours, and third-party inspections, which is a good sign of confidence in real production capability.

Building a Win–Win OEM Contract Structure

A good OEM mini excavator contract should:

- Give the buyer price competitiveness, reliable quality, and branding control.

- Give the factory stable orders, reasonable margin, and clear rules.

Some smart structures include:

Volume-based pricing and rebates

- Base price for low volume (e.g., 1–4 units per order).

- Better price for higher volume brackets (e.g., 5–9 units, ≥10 units).

- At the end of the year, a rebate based on total purchased volume.

This rewards the buyer for concentrating orders with one factory, and encourages the factory to maintain good quality so volumes grow.

Price adjustment clause

Instead of fighting again each time steel or engine suppliers change prices:

- Include a simple price adjustment clause tied to a public index or documented cost changes.

- Agree that if costs rise beyond a certain threshold, both sides renegotiate.

This prevents sudden surprise quotes and keeps the relationship transparent.

Quality and inspection plan

A robust contract usually defines:

- In-house factory inspection: every unit is tested and logged.

- Pre-shipment inspection: either buyer sends a representative, appoints a third-party inspection agency, or uses detailed photo/video reports.

- If defects above an agreed ratio are found, the factory reworks at its cost and supports inspection fee.

Nicosail and similar factories often already work with standard checklists and welcome pre-shipment inspections, especially for new OEM customers.

Example: Structuring a 1.8 Ton OEM Mini Excavator Project

To make this more concrete, imagine a buyer in Europe or Canada wanting to launch a private-label 1.8T mini excavator.

Basic specs agreed

- Operating weight: around 1.8 tons with standard bucket

- Engine: well-known compliant brand suitable for EU/NA emissions

- Hydraulic system: reliable gear pump with branded main valve

- Undercarriage: rubber tracks, fixed or expandable undercarriage based on local need

- Canopy machine with safety features; cab version as optional for later

OEM branding items

- Color: buyer’s brand yellow (RAL code), black undercarriage

- Side decals: buyer’s logo and model name (e.g. “MX18”)

- Serial plates: show buyer’s brand but also include manufacturing year and factory code (for traceability)

- Manual: English manual with buyer’s brand on cover, inside pages mention manufacturing by a Chinese factory according to local legal practice

A factory like Nicosail can take its existing 1.8T platform and adjust paint, logos, and some options to match this spec.

Negotiated commercial terms (illustrative)

- Price: FOB Chinese port, price per unit based on configuration

- MOQ:

- First test order: 4 units mixed colors allowed

- Regular order: minimum 6–8 units per shipment

- Lead time:

- First order: 30–40 days after deposit (time for new paint and decals)

- Repeat orders: 25–30 days

Quality and certificates

- CE compliance where needed, with technical documentation prepared by the factory

- Factory testing checklist annexed to contract

- Pre-shipment inspection by third-party once per batch for first two batches, then simplified process if no major issues.

Warranty and after-sales

- 12 months / 1000 hours warranty, with specific terms for engine and hydraulics

- Spare parts package for the first 20 machines, shipped with the first and second orders

- Technical support by email/video; if patterns of failure appear, root-cause investigation and corrective measures agreed.

Pricing and long-term cooperation

- Base price for small volumes in year 1

- Once yearly volume exceeds an agreed level, discount or rebate for the next year

- Price review every 6–12 months based on material and component cost evolution.

This kind of structure aligns both sides: the buyer can safely push the brand in the local market, and the factory benefits from repeat orders and predictable planning.

Practical OEM Negotiation Checklist

Before signing any contract, it helps to go through a checklist like this:

1. Supplier verification

- Real factory address confirmed

- Factory photos/videos or on-site visit

- Company registration documents checked

- Reference customers or export history confirmed

2. Technical agreement

- Final spec sheet for each model signed by both parties

- Color codes, logo files, and decal drawings approved

- Any special design or tooling clearly listed

3. Quality and testing

- Factory test checklist attached

- Leak and functional test requirements defined

- Pre-shipment inspection method agreed

4. Commercial terms

- Final FOB/CIF price and currency

- Payment terms (deposit, balance, LC if any)

- Lead time and delivery window

- MOQ per order and per year

5. Certificates and documents

- Required certificates listed and copies provided

- Manuals, spare parts lists, exploded drawings planned

- Any Notified Body or third-party documentation agreed

6. Warranty and after-sales

- Warranty period and coverage scope defined

- Spare parts availability period and pricing policy stated

- Initial parts package confirmed

7. Legal and IP

- Bilingual contract (Chinese + English) signed and chopped

- Confidentiality clause and OEM brand usage limitation included

- Tooling ownership and handling defined

Working through this list with a factory such as Nicosail significantly reduces surprises later and shows the supplier that the buyer is serious and organized.

FAQ: Common Questions About Chinese Mini Excavator OEM Contracts

1. How low can the price go without hurting quality?

There is always a bottom line. If price is pushed too low, the factory must save money somewhere: cheaper steel, thinner plates, no proper testing, weaker hoses, or cutting after-sales service. A realistic discussion of target price vs. configuration usually finds a safe balance. If one quote is radically lower than what established factories offer for similar specs, caution is advised.

2. Is it better to start with a Chinese engine or an imported brand like Kubota/Yanmar?

This depends on the target market:

- For markets where emission rules are strict and brand recognition is important, imported engines may be almost mandatory.

- For more price-sensitive markets with lower emission requirements, a reliable Chinese engine can be a good starting point, then upgrade later as the brand grows.

Factories like Nicosail can usually offer both options and explain the cost difference.

3. How to make sure certificates (like CE or EPA) are real?

Several simple checks help:

- Check that the factory name and address on certificates match the supplier.

- Ask for technical files or at least some technical documentation, not only a one-page certificate picture.

- Use a third-party testing or certification body if necessary.

In the contract, make valid certification a condition for shipment.

4. What is a reasonable lead time for OEM mini excavators?

For a serious factory:

- First OEM order with new colors and decals: usually around 30–40 days after deposit.

- Repeat orders with stable configuration: typically 20–30 days.

Lead times shorter than this for complex machines are often unrealistic unless stock is already available.

5. How can payment be made safer for the buyer?

Common methods include:

- T/T with 30% deposit and 70% before shipment, linked to inspection.

- Letter of Credit (LC) for larger orders, though this adds banking cost and complexity.

- Escrow or trade assurance platforms where available, particularly for first orders.

Many OEM buyers start with stricter payment terms and more inspections, then move to simpler terms with trusted factories like Nicosail once cooperation is stable.

6. How to protect the brand when sharing logos and design with a Chinese factory?

Protection is never 100%, but can be improved by:

- Signing a formal OEM and confidentiality agreement.

- Using a reputable factory with real long-term business rather than a small trading company.

- Registering the brand in key markets and, if possible, in China.

Serious factories value long-term cooperation and will not risk their business by misusing customers’ brands.

7. Can small buyers also get OEM service, or is it only for large distributors?

OEM is not only for big names. Many Chinese factories, including brands like Nicosail, accept modest first orders (for example 3–5 units per model) for serious buyers who show a clear plan. What matters more than order size is the level of professionalism and long-term potential.

8. What is the main mistake foreign buyers make when negotiating OEM contracts?

A common mistake is focusing only on price and ignoring the contract details: specs, quality control, warranty, documents, and realistic lead time. Another mistake is changing requirements frequently during production, which causes confusion and extra cost. Clear preparation and a structured contract prevent most headaches.

Final Summary

Negotiating Chinese mini excavator OEM contracts is not just about getting the lowest price. It is about locking in reliable quality, realistic lead times, proper certification, and strong branding—all written clearly into a bilingual contract that both sides understand.

Key points to keep in mind:

- Prepare a clear market positioning and volume plan before contacting factories.

- Turn vague promises into written terms: spec sheets, QC checklists, certificates, warranty and spare parts arrangements.

- Use negotiation to build a win–win structure: volume-based pricing, sensible payment terms, and transparent price adjustments.

- Work only with factories that show real production capacity, openness to inspection, and stable export experience. Brands like Nicosail can be strong partners here, offering existing mini excavator platforms with OEM customization for color, logo and configuration.

Handled in this way, an OEM project in China stops being a gamble and becomes a controlled, scalable business tool—allowing dealers, rental companies and importers to build solid private-label mini excavator lines with confidence.